Finally Figured Out Why Single-Face Machines Determine the Upper Limit of Corrugated Board Quality

Fortunately, together with everyone, I'm witnessing a “structural evolution” in China's corrugated board industry.

Over the past year, I've been immersed in factory sites, equipment upgrades, and customer commissioning. Working alongside the technical team, we've dismantled dozens of single-face machines and witnessed countless corrugated boards transition from “wavy” to “smooth.”

Gradually, I came to realize:

What determines corrugated board quality isn't just the base paper, nor the production speed—it's the logic of the single-face machine.

It sounds simple, yet nearly 90% of industry issues can be traced back to this fundamental principle.

01.The First Pitfall: Assuming Single-Face Machines Are Just “Heat + Pressure + Adhesion”

Years ago, our understanding of corrugators remained at the process level: Is the temperature sufficient? Is the pressure stable? Is the adhesive application uniform?

Back then, the industry's mantra was “speed up”—300 m/min, 350 m/min, 400 m/min.

Everyone pursued faster speeds while overlooking a fundamental truth:

A corrugator isn't a mechanical structure; it's a dynamic system.

It simultaneously manages three distinct physical processes:

Heat transfer (steam heating, gelatinization)

Mechanical pressure (corrugation forming, liner lamination)

Chemical reactions (adhesive rheology)

Fluctuations in any single process are amplified within microseconds, ultimately manifesting on the board surface as warping, de-bubbling, incomplete lamination, uneven thickness, and weak bonding layers.

Thus you discover:

Even with premium base paper and imported paste, the board remains unstable.

The root issue lies not in materials, but in “synergy.”

The single facer isn't an executor—it's the “system commander.”

02.The Second Pitfall: Applying Old Thinking to New Equipment

Traditional papermaking equipment logic prioritized “stability”—fixed parameters, mechanical control.

But modern board production has evolved into an information-driven system.

Base paper weight, moisture content, steam pressure, adhesive viscosity—all fluctuate constantly.

Yet many factories still rely on static settings to manage dynamic processes.

It's like building an airplane using horse-drawn carriage methods—it simply won't fly.

Modernizing a single-face machine isn't about “upgrading,” but “paradigm shift.”

It transforms from mechanical equipment into an intelligent system, shifting from temperature control to logic control.

True advancement lies not in pricier components, but in grasping the data patterns underlying the process.

03.The Third Pitfall: Underestimating the Power of “Fine-Tuning”

Many factory owners share this frustration:

“That machine runs at 350 at others' plants, but ours starts malfunctioning at 300.”

Why?

Because corrugated board quality stability depends not on “maximum speed,” but on parameter alignment.

Each component of a single-face machine—temperature zones, gluing sections, pressure zones, transmission rhythms—functions like interlocking gears.

If any rhythm falls out of sync, even by 0.5 seconds, it can ruin an entire roll of cardboard.

Many invest millions in new machines while overlooking that the “machine-tuner's expertise” is the most valuable asset.

This is why future single-face machines must possess “learning capabilities.”

04.The Fourth Pitfall: Disconnected Processes, Equipment, and Data

Today's single-face machine issues are increasingly less about “hardware problems” and more about “system integration problems.”

Temperature control systems and steam systems don't communicate; adhesive viscosity goes unmonitored; drive rhythms are disconnected from wet-end signals.

This means production sites are essentially flying blind.

The real breakthrough isn't replacing a single piece of equipment, but establishing a perception-feedback-adaptation cycle.

Our Approach: Enabling Single-Faced Machines to “Understand” Paperboard

The upper limit of paperboard quality isn't determined by paper thickness, but by whether the equipment can comprehend the paper.

This “understanding” isn't about sensor quantity, but adaptive response to dynamic conditions.

It requires three elements:

System Modeling—Real-time computational models for temperature, pressure, sizing, and speed;

Closed-Loop Process Parameter Control—Data-driven adjustments, not manual experience;

Learning Mechanism—Enabling the machine to accumulate experience from every production run.

The Brand Divide: Who Builds Systems, Who Assembles Machines

Many generic single-face machines on the market remain stuck at the “can run, can glue, can produce cardboard” stage.

Their electronic components lack standardization, pneumatic parts are unreliable, and long-term data consistency is absent.

The result: Fast performance for the first three months, followed by constant issues after a year.

In corrugated cardboard production, equipment stability defines a company's survival threshold.

Yet many carton factories face daily realities like:

— Cardboard thickness varies and warping is severe;

— Temperature control on single-face machines fluctuates wildly;

— Transmission is out of sync and generates excessive noise;

— Frequent downtime and unpredictable output.

What appears as mere “machine instability” actually stems from systemic issues in equipment design, component selection, and maintenance standardization.

Many factories invest substantial labor and time, yet continue patching up an “unreliable production system.”

LUM understands this deeply.

We believe a superior single-face machine isn't merely “operational”—it consistently maintains precision and uniformity under sustained high-intensity production.

This is why we insist on using international brand components from Schneider, Delixi, YADAK, Tengzhou, and others,

while implementing engineering-grade optimizations across three critical systems: control, pneumatic circuits, and transmission.

Stability means predictable quality;

Predictable quality is the foundation of corporate profitability.

As Peter Drucker stated:

“What cannot be measured cannot be managed; what cannot be managed cannot be improved.”

Every fluctuation in corrugator performance multiplies impacts on board quality, energy consumption, and labor costs.

True competitiveness lies not in how fast you repair, but in making equipment “unrepairable.”

LUM makes stability the norm in production.

LUM's Five Speed Solutions for Factories of All Sizes

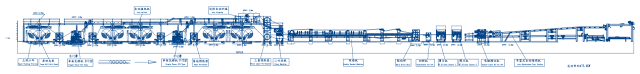

LUM designs five speed tiers of single-face machines for carton factories of varying capacity and scale:

LUMA / LUMB Standard Single-Face Machines: Ideal for small to medium carton factories, offering high cost-effectiveness and simple maintenance;

LUMC Fixed Heavy-Duty Single-Facer: Engineered for medium-to-large factories, delivering exceptional stability for extended continuous production;

LUMD / LUMS Quick-Change Single-Facer: Enables 15-minute job changeovers, effectively saving paper and time while boosting order transition efficiency.

Regardless of output volume, LUM provides optimal speed ratio matching and process stability support.

Final Thoughts

Facing machines are no longer mere equipment—they are the logical hub of corrugated board quality.

Whoever enables machines to understand corrugated board will define the industry's new standards.

LUM has chosen a path toward an engineered, systematic, and intelligent future.

—LUM Lincheng Packaging Machinery

Comments

Post a Comment