Chances are you don't know about corrugated cardboard boxes

1. The production process of corrugated cardboard boxes

It mainly includes: box making, printing and gluing. During this process, various performance tests need to be conducted on corrugated boxes, including edge compression strength, breakage resistance, puncture strength, compressive strength and flexural strength. These tests need to be carried out in specific environments, such as humidity and temperature control. Corrugated base paper is generally manufactured from ground wood pulp, semi-chemical pulp, waste paper pulp, etc. It is also manufactured from mixed pulps. In the past, most of the domestic corrugated base paper was made from grass pulp with some semi-chemical pulp or waste paper pulp.

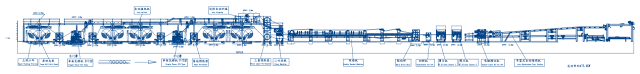

https://www.linchengpack.com/3/5/7-ply-corrugated-cardboard-production-line560

2. Core Functions

Cushioning, anti-pressure, protection of goods, both printing and display function.

International Standard Classification

FEFCO/ASSCO standard: use 4-8 digits to indicate the box type.

U.S. and Japanese standards: such as the U.S. FBA certification box type, Japan JIS Z 1507 standard.

3. Raw paper type

style | specificities | application scenario |

kraft paper | High strength, sustainable (wood pulp-based) | High-end transportation boxes, heavy-duty packaging |

coated paper | Smooth surface, good printing effect | Color box, sales package |

recycled paper | Low cost, environmentally friendly but less strong | Lightweight packaging, lining |

Corrugated Type Comparison

Flute type | Flute height(mm) | Flute amount(pc) | features | Applicable Scenarios |

A | 4.5-5.0 | 34±2 | Good cushioning, average pressure resistance | Transportation of fragile products |

B | 2.5-3.0 | 50±2 | High compression resistance and plane hardness | Food boxes, retail packaging |

C | 3.5-4.0 | 40±2 | Balanced cushioning and pressure resistance | Universal Transportation Box |

E/F | <1.5 | 90+/120+ | Thin and light with fine printing | Electronic products, display packaging |

Layer Selection Guide

Single-layer: liner, mat board.

Three-layer (single corrugated): light goods (e.g. express boxes).

Five-layer (double corrugated): home appliances, glass products.

Seven-layer: alternative to wooden boxes for heavy-duty home appliances and equipment, etc.

4. Critical Computing and Testing

Carton area formula

Single barge box: total length = (length + width) × 2 + joints

Double barge box: total length = (length + width + joint) x 2

Total width = width + top flap size + bottom flap size

Weight Calculation Example

Grammage of AB pit board = Grammage of face paper + Grammage of B flute × 1.36 + Grammage of core paper + Grammage of A flute × 1.51 + Grammage of backing paper

Example: If the top paper is 300g, B flute is 120g, core paper is 150g, A flute is 180g, and bottom paper is 300g, then the total grammage = 300 + (120 x 1.36) + 150 + (180 x 1.51) + 300 ≈ 1246g/㎡.

Performance Test Criteria

Test Type | goal | International standard reference |

Side Pressure Test | Assessment of vertical stress tolerance (ECT) | ISO 3037 |

Box Pressure Test | Analog stacking compressive (BCT) | ASTM D642 |

Breakage resistance test | Testing the strength of cardboard against partial rupture | ISO 2758 |

5. Environmental Trends and Innovations

Sustainable Materials

Recycled pulp: Increase the proportion to over 60% to reduce carbon emissions.

Bio-based coating: replacing PE lamination for biodegradability.

Lightweight design

Reduce material usage and maintain strength by optimizing flute combinations (e.g. EB pit).

BMC Certification

The common European quality marking ensures that the carton passes tests such as edge compression and breakage resistance and meets the requirements of the circular economy.

6. Common Application Scenarios

E-commerce logistics: B flute three-layer box (balancing cost and pressure resistance).

Fresh food cold chain: BC five-layer box + moisture-proof coating.

Luxury goods: F-flute micro-corrugated + high-precision printing.

Comments

Post a Comment