Vigilance! The “purchase of machinery” is not a small matter, but a strategic investment for the future direction of the enterprise!

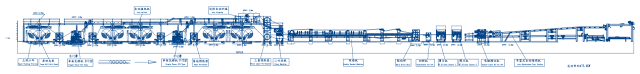

The introduction of a production line is not a simple purchase, but the subsequent process covers a number of key aspects such as installation, commissioning and test run. In this process, whether the equipment frequently breaks down, or the quality of the cardboard is not up to standard due to the machine's own problems, which leads to a lot of additional time and cost loss, are all issues that must be emphasized. In addition, once the equipment fails, the seller's response speed and the timeliness of after-sales treatment are also crucial. If the after-sales processing is not timely, not only may lead to order default, facing liquidated damages, but also negatively affect the credibility of the enterprise, at the same time, the order backlog generated by the intangible costs, should not be underestimated, which will ultimately be transformed into a cost burden on the enterprise.

If you have a large budget, you can prioritize high-performance production line equipment. This type of equipment not only runs fast, high production efficiency, and requires less manpower. Although the initial purchase of capital investment is large, but a one-time purchase in place, later without frequent replacement, in the long run, can significantly save the subsequent labor costs, is undoubtedly a wise choice for the long-term development of enterpris

In the case of limited budget, it may be worth considering the configuration of a lower fully automatic production line, this type of equipment requires less manpower, to be followed by profitability, and then gradually replaced by machinery with better performance, semi-automatic equipment can be used as a temporary transition program first.

If the local labor cost is low, manual and semi-automatic machines are also a good choice, which are cost-effective and economical. Consideration can be given to increasing the number of single-face machines, for example, by configuring two single-face machines, the production of composite fluting can be realized, which basically meets the needs of various types of fluting.

Combined with the actual situation of the enterprise itself to buy production line is extremely necessary. From a long-term perspective, this is a solid cornerstone for the steady development of enterprises, helping enterprises to steadily improve their strength, and gradually open up new markets. This is by no means a simple “purchase of machinery and equipment”, but a strategic investment in the future direction of the enterprise.

Comments

Post a Comment