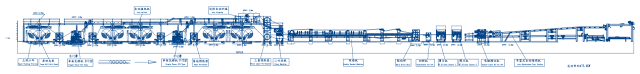

The Role of Single Facer Machines in Corrugated Cardboard Production Lines

In the global corrugated packaging industry, efficiency and precision are everything. Among the core components of a corrugated cardboard production line, the single facer machine plays one of the most decisive roles. It determines the stability, strength, and quality of the corrugated medium — the heart of every carton box.

As carton manufacturers, corrugated board converters, and packaging machinery distributors increasingly seek high-speed, flexible production solutions, the single facer has become a critical investment for improving output and product diversity.

What Is a Single Facer Machine?

A single facer is the fundamental unit of a corrugated cardboard production line that bonds one liner paper and one corrugated medium to form a single-faced corrugated board. This intermediate product later becomes the core of double-wall or triple-wall boards after lamination.

The single facer is responsible for:

-

Forming the corrugation (fluting) through heated corrugating rolls

-

Applying adhesive precisely on the flute tips

-

Bonding the liner to produce single-face paperboard

It’s often referred to as the “heart of the corrugator” because the consistency of flute formation directly determines the performance of the final cardboard — from strength and flatness to printability and folding endurance.

Market Demand and Global Trends

According to Smithers (2024), the global corrugated packaging market is expected to reach USD 362 billion by 2029, driven by e-commerce, food delivery, and sustainability demands. As packaging converters upgrade to automated systems, the adoption rate of high-speed single facers has increased by 27% in the past five years (source: Packaging Machinery Insights, 2023).

Manufacturers are now focusing on:

-

Energy-efficient systems with precise temperature and humidity control

-

Quick-change corrugating roll systems for faster order switching

-

Stable bonding performance to avoid warping or delamination

These market drivers highlight why upgrading the single facer is often the first step in modernizing a corrugated production line.

Why the Single Facer Matters

A high-performance single facer determines:

-

Production Speed – The faster the corrugation process, the higher the overall line output.

-

Quality Consistency – Stable flute geometry and adhesive control prevent warping and bonding issues.

-

Material Efficiency – Advanced glue application systems reduce waste and save raw materials.

-

Flexibility – The ability to switch flute types (A, B, C, E, F) enables diversified product lines.

Many of our long-term customers begin their production line upgrades with the single facer. A modern single facer doesn’t just boost output — it enhances competitiveness by adapting to multi-flute production and custom packaging trends.

LUM Single Facer Solutions

Founded in 1999, LUM Packaging Machinery has specialized in corrugated machinery design, manufacturing, and service for over two decades. Our factory spans over 20,000 square meters, serving more than 80 countries and regions worldwide.

We provide CE and CQC-certified single facer machines, tailored to meet different speed and production demands — from standard to high-speed quick-change models.

🔗 Learn more about LUM Single Facer Machines

Model Overview

1. Standard Single Facer – LUM-A / LUM-B

Specifications:

-

Working Width: 1400–2200 mm

-

Speed: 120–150 m/min

-

Pressure Roll Diameter: Φ270/Φ280 mm (45# steel) or Φ320 mm (45# steel)

Key Features:

-

Corrugating rolls made of high-quality alloy steel, hardened, tempered, and polished.

-

Pneumatic lift control for corrugating rolls ensures precise flute forming.

-

Vacuum suction and high-pressure air system guide the paper smoothly.

-

Electric glue width adjustment, with independent glue unit operation (prevents glue drying during stop).

-

Digital glue quantity control, steam preheater, and atomizing humidifier to maintain paper moisture balance.

-

Equipped with reliable components from Schneider, Delixi, Airtac, and Tengzhou.

2. Quick-Change Single Facer – LUM-S

Specifications:

-

Working Width: 1400–2800 mm

-

Speed: Up to 300 m/min

-

Pressure Roll Diameter: Φ320 / Φ360 / Φ408 mm (optional)

Key Features:

-

Negative pressure design ensures uniform flute formation and perfect adhesive application.

-

Quick-change corrugating roll unit allows roll replacement within 15 minutes using an electric trolley system — minimizing downtime and material waste.

-

Airbag pressure system for corrugating, pressure, and glue rolls provides stable tension and cushioning.

-

Electric glue width and dosage adjustment, with independent glue section operation to prevent drying when idle.

-

PLC touchscreen interface with colored display and user-friendly controls.

-

Atomizing humidification system to control temperature and moisture of the medium paper.

-

Premium components from international brands ensure durability and operational safety.

This model is designed for high-speed corrugated production lines requiring frequent flute changes and maximum efficiency — ideal for modern, multi-grade carton manufacturers.

Technical and Operational Advantages

| Feature | LUM-A/B Standard Model | LUM-S Quick-Change Model |

|---|---|---|

| Production Speed | 120–150 m/min | Up to 300 m/min |

| Corrugating Roll Change | Manual / Pneumatic | Electric quick-change within 15 min |

| Pressure System | Pneumatic | Airbag with pneumatic buffer |

| Glue Control | Electric width adjustment | PLC digital control |

| Humidity Regulation | Spray humidifier | Atomizing mist + temperature control |

| Maintenance | Basic | Intelligent with fast service access |

Practical Example: Why Customers Upgrade Their Single Facer

One of our long-term customers, a packaging factory in Southeast Asia, upgraded from a 150 m/min standard model to our LUM-S 300 m/min quick-change single facer. The results were immediate:

-

Production efficiency increased by 45%

-

Order changeover time reduced by 70%

-

Paper waste decreased by 12% per shift

Their decision mirrors a common industry trend — upgrading the single facer first is often the most cost-effective way to improve a corrugated line’s overall performance.

Certifications and Global Support

All LUM single facer machines comply with international standards (CE, CQC).

We welcome global clients to visit our factory, evaluate our running machines, and discuss tailored corrugator solutions with our engineers.

LUM provides complete technical training, after-sales service, and spare parts support to ensure long-term operational reliability.

Conclusion

The single facer is more than just one machine — it’s the foundation of quality corrugated board production. Its precision in forming and bonding directly determines the speed, stability, and final appearance of every carton you produce.

By upgrading to an advanced, quick-change, and energy-efficient single facer, carton manufacturers can significantly enhance productivity, reduce waste, and meet the growing market demand for diverse packaging formats.

🔗 Explore LUM Corrugated Single Facer Machines Here

References

-

Smithers – The Future of Corrugated Packaging to 2029 (2024)

-

Packaging Machinery Insights – Global Corrugator Equipment Report (2023)

-

Statista – Corrugated Board Production Volume Worldwide (2024)

Comments

Post a Comment