The Complete Guide to Selecting Corrugator: Comprehensive Considerations from Needs Assessment to Implementation

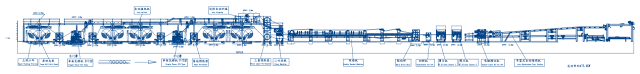

When consumers face the decision of purchasing a corrugator, they often find themselves at a loss. After all, the market offers a vast array of corrugator models with varying configurations. Selecting equipment that aligns with specific needs requires a solid grasp of fundamental knowledge. As essential machinery in the packaging industry, corrugators primarily handle the production of corrugated cardboard. Production lines of different scales and requirements demand distinct corrugator types, necessitating a comprehensive evaluation of multiple factors during the selection process.

Define your production requirements

Before purchasing a corrugator, the primary task is to clearly define your production requirements. This encompasses key factors such as the types of corrugated board planned for production, average daily output, and facility conditions. For instance, if a company's operations primarily focus on producing Type B or Type C corrugated board with relatively low daily output demands, a single-face corrugator may suffice. However, if the company requires production of multiple flute types with larger output volumes, a double-face machine or a more comprehensive production line may be the more suitable choice. Additionally, the size of the factory space and electrical power configuration will also influence equipment selection. For instance, certain large corrugators not only occupy significant floor space but also require high-voltage electrical support.

Focus on the quality of core components in equipment

The quality of a machine's core components directly impacts production efficiency and product quality. Among these, the corrugating rollers serve as the “heart” of the corrugator. Their material composition and manufacturing process directly determine the equipment's service life and the forming quality of the corrugated board. High-quality corrugating rollers ensure consistent flute profiles and meet strength standards, thereby enhancing the overall product quality. Simultaneously, the heating system must not be overlooked. Currently, steam heating and electric heating are the two predominant heating methods in the market, each with its own advantages and disadvantages. Enterprises should make informed choices based on local energy supply conditions and cost considerations. Furthermore, with technological advancements, most corrugators now incorporate automated control systems. A well-designed control system significantly improves operational convenience and stability while minimizing the impact of human operational errors.

Consideration of energy consumption and maintenance costs

During the long-term operation of equipment, energy consumption represents a significant cost that cannot be overlooked. Different models of corrugators exhibit notable variations in power consumption. Therefore, when selecting equipment, consumers should prioritize the energy efficiency rating, opting for higher-efficiency products to reduce long-term operating costs. Beyond energy consumption, maintenance costs are another critical factor requiring careful consideration. This includes the replacement frequency of wear-and-tear parts and the ease of repairs. Some equipment may have a lower initial purchase price, but frequent replacement of wear parts and difficult repairs can lead to persistently high maintenance costs over time. Therefore, when purchasing equipment, one should not focus solely on the initial investment but must comprehensively evaluate the total cost of ownership over the equipment's long-term use.

Prioritize after-sales service support

After-sales service is a crucial pillar for ensuring stable equipment operation. When selecting a corrugator, it is essential to understand the supplier's response time, technical support capabilities, and spare parts availability. During equipment operation, various issues are inevitable. Prompt after-sales service and technical support enable swift troubleshooting, minimizing downtime and reducing production losses caused by stoppages. For instance, when equipment malfunctions, whether the supplier can dispatch technicians for repairs within a short timeframe and whether spare parts can be supplied promptly directly impact the equipment's normal operation and the company's production schedule.

Field visits and user feedback

Before purchasing a corrugator, conducting an on-site inspection of the equipment's operation is highly beneficial. If possible, consumers should visit the supplier's customer factories to observe the equipment in actual production environments. By evaluating factors such as operational stability, production efficiency, and product quality, one can gain a more intuitive understanding of the equipment's performance. Simultaneously, gathering feedback from existing users provides valuable firsthand insights. The experiences and challenges these users have encountered during actual operation offer crucial reference points for consumers' purchasing decisions.

Reasonably plan the budget

Budget planning also plays a crucial role when selecting a corrugator. The price range for corrugators on the market varies significantly, spanning from several hundred thousand to several million RMB. Consumers must determine a reasonable budget based on their actual needs and financial situation. It is essential to avoid overspending due to excessive pursuit of high-end configurations, which can lead to wasted funds, while also preventing the selection of inadequate equipment due to insufficient budget, which could compromise production efficiency and product quality.

Frequently Asked Questions

How to determine the production efficiency of a corrugator?

To assess the production efficiency of a corrugator, one can refer to its technical specifications, such as maximum operating speed and preheating area. However, actual production efficiency is not solely determined by the equipment itself but is also influenced by various factors, including operator proficiency and raw material quality. For instance, even with excellent technical specifications, actual production efficiency may fall short of expectations if operators are unfamiliar with the equipment's operating procedures or if raw material quality is inconsistent.

How should one choose between new and old equipment?

New equipment and used equipment each have their respective advantages and disadvantages. New equipment typically incorporates more advanced technology and comes with more comprehensive warranty services, but it also involves higher investment costs. Used equipment, on the other hand, requires lower initial investment, making it attractive to companies with limited budgets. However, it may necessitate higher maintenance expenses and potentially have a relatively shorter service life. Therefore, when making a selection, companies need to conduct a comprehensive assessment based on their actual budget and technical capabilities.

What should be noted during equipment installation?

Equipment installation is a critical step. Prior to installation, the site, power supply, and other supporting facilities must be prepared in advance to meet the equipment requirements. For example, ensure the site floor is level and has sufficient load-bearing capacity, and that the power supply is stable and meets the equipment's voltage and power requirements. Additionally, installation should ideally be performed by qualified technicians to ensure proper positioning and commissioning of the equipment, thereby preventing performance issues and reduced service life caused by improper installation.

What training is required for operators?

Operators must undergo comprehensive training to master the equipment's fundamental principles, daily operational procedures, and methods for identifying and resolving simple malfunctions. Reputable equipment suppliers typically provide corresponding operational training services to help operators quickly become familiar with equipment operation and maintenance. Through training, operators can operate the equipment more proficiently, promptly detect and resolve common faults, and enhance the equipment's operational efficiency and stability.

Selecting a corrugator is a complex process requiring comprehensive consideration of multiple factors. Only by clearly defining your requirements, thoroughly understanding equipment performance, and fully evaluating the supplier's service capabilities can you find the equipment best suited to your production needs. Throughout this process, consumers should maintain a rational approach—neither blindly pursuing high-end configurations nor solely relying on price as the deciding factor. This ensures the selection of a corrugator that truly meets actual production requirements.

Comments

Post a Comment