The solution to the problems of warping, easy to break and poor bonding of cardboard cartons (I).

Purchase single facer with spraying device, here we recommend LUM's single facer (LUM-C heavy-duty ,suitable for single-volume factories), LUM-S quick-change (suitable for factories requiring speed), LUM-B ordinary single facer (suitable for small and medium-sized factories, the king of the cost-effective), the above single face machines are equipped with spraying device.

https://www.linchengpack.com/corrugator-single-facer

A brief introduction to the Single Facer:

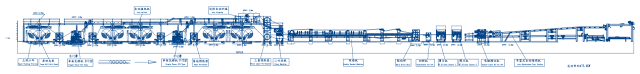

The Single Facer is one of the core equipments of a corrugated board production line. It is responsible for gluing, heating and pressurizing the liner and corrugated medium to form a single-faced corrugated board. Its operation directly affects the molding quality, strength and production efficiency of the corrugated board.

Role of the single-faced machine in the corrugated production line

Corrugating: The core paper is pressed into a wave shape (A flute, B flute, C flute, etc.) by corrugating rolls.

Gluing and laminating: Evenly apply glue to the corrugated peaks to bond with the top paper.

Preliminary shaping: Initial curing of the glue by heat and pressure to form a stable single-sided corrugated structure.

If the single facer runs unstably, it may result in:

Poor corrugated molding (high and low flute, collapsed flute)

Poor gluing (false gluing, de-gluing)

Cardboard bending (warping due to uneven humidity or temperature)

Focus: How to optimize the single facer to reduce sheet bending problems?

1. Control corrugator roll temperature and pressure

Temperature: Usually controlled at 160-180°C (adjusted according to paper grade) to ensure fast glue gluing.

Pressure: The gap between the corrugator rolls should be adjusted appropriately. If it is too large, the flute will be flattened, while if it is too small, the glue will not be firmly bonded.

2. Glue making system

Glue Viscosity: Glue that is too thin will lead to infiltration, while glue that is too thick will affect bonding.

Glue quantity: usually 10-15g/m² for single facer, it should be evenly coated, avoiding too much or too little locally.

Glue formula: adjust according to season.

3. Preheating and humidity balance

Pre-heating roll temperature: face and core paper need to be pre-heated to the right moisture to prevent bending due to uneven moisture.

Steam Spray: Slightly humidify the paper that is too dry, but avoid overdoing it to cause the glue not to dry.

4. Mechanical Adjustment

Parallelism of corrugated rolls: Ensure that the upper and lower corrugated rolls are perfectly parallel to avoid uneven pressure on one side.

Cleanliness of the paper guide rolls: Prevent the accumulation of paper dust, which affects the flatness of the paper.

Tension control: Stabilize the paper feed force to avoid paper stretching and deformation.

5. Production parameter matching

Speed and temperature coordination: When the production line speed increases, the heating temperature should be increased accordingly to ensure that the glue is fully cured.

Shutdown management: When the production line is shut down for a long period of time, the temperature of the corrugated rolls should be lowered to prevent the paper from being deformed due to localized overheating.

Summarizing

Stable operation of the single-face machine is crucial to the quality of corrugated board. Temperature control, glue management, mechanical adjustments and optimization of production parameters can effectively reduce paper bending problems caused by changes in dryness and humidity. At the same time, regular maintenance of the equipment (e.g., cleaning corrugated rolls, checking the pressure system) can also significantly improve productivity and product qualification rates.

For the cardboard carton production of common warping, easy to break and bonding problems, currently provides three main solutions. In this paper, we will firstly explain one of the key technologies - the application principle of the single face machine and its functioning mechanism, as well as its need to cooperate with the instrumentation.

Comments

Post a Comment